標準

GB812 |

名稱

圓螺母,開槽圓螺母 |

英文名

Round nuts |

近似標準

GB810

|

材質

碳鋼、不銹鋼 |

表面

本色、電鍍... |

特點

防松、防振、止退 |

||

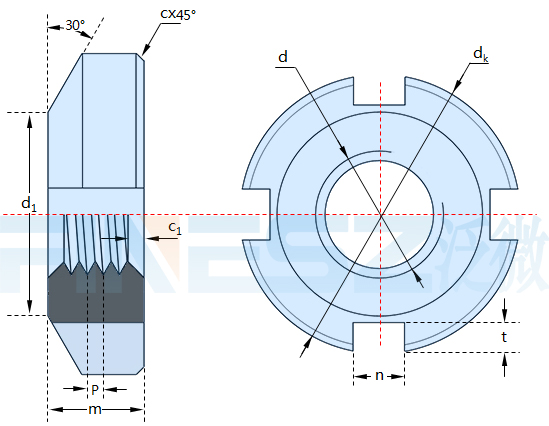

GB812圓螺母常與GB858圓螺母用止動墊圈 配合使用。裝配時,先將墊圈內舌對準被安裝的軸的鍵槽內并套入軸;再將螺母旋擰入軸(30°斜面端為擰入面)且鎖緊;將墊圈任一外舌折彎并嵌入圓螺母的槽內

配合使用。裝配時,先將墊圈內舌對準被安裝的軸的鍵槽內并套入軸;再將螺母旋擰入軸(30°斜面端為擰入面)且鎖緊;將墊圈任一外舌折彎并嵌入圓螺母的槽內 。裝配完成的螺母由于墊圈的駁接作用,不會再發生旋轉,從而起到防松作用。

。裝配完成的螺母由于墊圈的駁接作用,不會再發生旋轉,從而起到防松作用。

GB812螺母與GB858墊圈成對地用于機器的軸類零件上,用以防止軸向位移;以及用于裝有滾動軸承的軸上,鎖緊軸承內圈。圓螺母的裝拆須用專用的鉤形扳手。

網址鏈接:

圓螺母止動墊圈:GB858-88.pdf

圖紙:

尺寸表(單位:MM)

| 螺紋尺寸 d | |

| P | |

| dk | |

| d1 | |

| m | |

| n | 最大值 |

| 最小值 | |

| t | 最大值 |

| 最小值 | |

| c | |

| c1 | |

| 千件重(鋼制)≈kg | |

| M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M25 | M27 | M30 | M33 | M35 | M36 | M39 | M40 | M42 | M45 | M48 | M50 | M52 | M55 | M56 | M60 | M64 | M65 | M68 | M72 | M75 | M76 | M80 | M85 | M90 | M95 | M100 | M105 | M110 | M115 | M120 | M125 | M130 | M140 | M150 | M160 | M170 | M180 | M190 | M200 |

| ×1 | ×1.25 | ×1.5 | ×1.5 | ×1.5 | ×1.5 | ×1.5 | ×1.5 | ×1.5① | ×1.5 | ×1.5 | ×1.5 | ×1.5① | ×1.5 | ×1.5 | ×1.5① | ×1.5 | ×1.5 | ×1.5 | ×1.5① | ×1.5 | ×2 | ×2 | ×2 | ×2 | ×2① | ×2 | ×2 | ×2① | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×2 | ×3 | ×3 | ×3 | ×3 | ×3 |

| 22 | 25 | 28 | 30 | 32 | 35 | 38 | 42 | 42 | 45 | 48 | 52 | 52 | 55 | 58 | 58 | 62 | 68 | 72 | 72 | 78 | 78 | 85 | 90 | 95 | 95 | 100 | 105 | 105 | 110 | 115 | 120 | 125 | 130 | 135 | 140 | 150 | 155 | 160 | 165 | 170 | 180 | 200 | 210 | 220 | 230 | 240 | 250 |

| 16 | 19 | 20 | 22 | 24 | 27 | 30 | 34 | 34 | 37 | 40 | 43 | 43 | 46 | 49 | 49 | 53 | 59 | 61 | 61 | 67 | 67 | 74 | 79 | 84 | 84 | 88 | 93 | 93 | 98 | 103 | 108 | 112 | 117 | 122 | 127 | 135 | 140 | 145 | 150 | 155 | 165 | 180 | 190 | 200 | 210 | 220 | 230 |

| 8 | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 12 | 15 | 15 | 15 | 15 | 15 | 18 | 18 | 18 | 18 | 18 | 22 | 22 | 22 | 22 | 26 | 26 | 26 | 26 | 30 | 30 | 30 |

| 4.3 | 4.3 | 4.3 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | 5.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 6.3 | 8.36 | 8.36 | 8.36 | 8.36 | 8.36 | 8.36 | 8.36 | 8.36 | 10.4 | 10.4 | 10.4 | 10.4 | 10.4 | 10.4 | 12.4 | 12.4 | 12.4 | 12.4 | 14.4 | 14.4 | 14.4 | 14.4 | 14.43 | 14.43 | 16.43 | 16.43 | 16.43 | 16.43 | 16.4 | 16.4 |

| 4 | 4 | 4 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 14 | 14 | 16 | 16 | 16 | 16 | 16 | 16 |

| 2.6 | 2.6 | 2.6 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.1 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 3.6 | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 | 4.25 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | 5.75 | 5.75 | 5.75 | 5.75 | 6.75 | 6.75 | 6.75 | 6.75 | 6.75 | 6.75 | 7.9 | 7.9 | 7.9 | 7.9 | 7.9 | 7.9 |

| 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 4 | 4 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 7 | 7 | 7 | 7 | 7 | 7 |

| 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 2 | 2 | 2 | 2 |

| 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 16.8 | 21.6 | 26.8 | 28.4 | 31.2 | 37.3 | 54.9 | 68.9 | 65.9 | 75.5 | 82.1 | 93.3 | 84.99 | 100 | 107 | 103 | 122 | 154 | 201 | 187 | 238 | 214 | 290 | 320 | 352 | 342 | 380 | 518 | 478 | 562 | 608 | 641 | 796 | 835 | 873 | 895 | 1076 | 1369 | 1423 | 1477 | 1531 | 1937 | 2651 | 2810 | 2970 | 3610 | 3794 | 3978 |

| 材料 | 45鋼(GB 699) | |

| 螺紋 | 公差 | 6H |

| 標準 | GB 196、GB 197 | |

| 垂直度 | 標準 | GB 1184 |

| 熱處理及表面處理 | ①槽或全部熱處理后HRC 35~45 ②調質HRC 24~30 ③氧化 |

|

| 驗收及包裝 | GB 90 | |

蘇公網安備32058102001839

蘇公網安備32058102001839