標準

DIN934-1987.pdf |

名稱

六角螺母 |

英文名

Hex Nut |

近似標準

GB/T 6170.pdf、ISO4032-2012.pdf |

表面

本色,鈍化,電鍍... |

|

性能等級 A2-50 A2-70 A4-70 A4-80 4.8 6.8 8.8 10.9 12.9

|

應用領域

通用 |

|

DIN934六角螺母在機械設計、汽車、建筑和其他工業領域有著廣泛的應用,其規格與幾乎遍歷了所有機械螺紋尺寸,是最常用的緊固件之一,也是結構最為簡單的緊固件之一。

DIN934螺母等效于ISO4032;除個別規格外,也可以等效于GB/T 6170。

德標原文檔:DIN934-1987.PDF

替代標準:ISO4032-2012.PDF

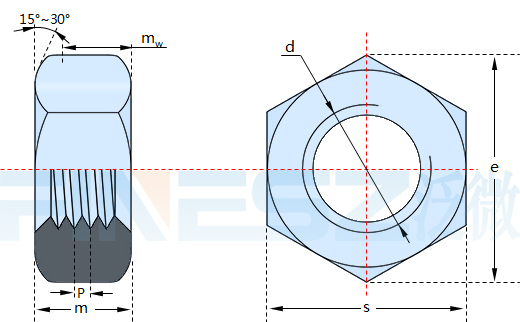

圖紙:

尺寸表(單位:MM)

| 螺紋尺寸d | ||

| P | 螺距 | 粗牙 |

| 細牙1 | ||

| 細牙2 | ||

| m | 最大值=公稱 | |

| 最小值 | ||

| mw | 最小值 | |

| s | 最大值=公稱 | |

| 最小值 | ||

| e ① | 最小值 | |

| * | ||

| 千件重(鋼制)≈kg | ||

| M1 | M1.2 | M1.4 | M1.6 | (M1.7) | M2 | (M2.3) | M2.5 | (M2.6) | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | (M45) | M48 | (M52) | M56 | (M60) | M64 | (M68) | M72 | (M76) | M80 | (M85) | M90 | M100 | M110 | M125 | M140 | M160 |

| 0.25 | 0.25 | 0.3 | 0.35 | 0.35 | 0.4 | 0.45 | 0.45 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 | 6 | / | / | / | / | / | / | / | / | / | / |

| / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 1 | 1 | 1.5 | 1.5 | 1.5 | 1.5 | 2 | 1.5 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | / | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | / | 1.25 | 1.25 | / | / | 2 | 1.5 | 2 | / | / | / | / | / | / | / | / | / | / | / | / | / | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | / | / |

| 0.8 | 1 | 1.2 | 1.3 | 1.4 | 1.6 | 1.8 | 2 | 2 | 2.4 | 2.8 | 3.2 | 4 | 5 | 5.5 | 6.5 | 8 | 10 | 11 | 13 | 15 | 16 | 18 | 19 | 22 | 24 | 26 | 29 | 31 | 34 | 36 | 38 | 42 | 45 | 48 | 51 | 54 | 58 | 61 | 64 | 68 | 72 | 80 | 88 | 100 | 112 | 128 |

| 0.55 | 0.75 | 0.95 | 1.05 | 1.15 | 1.35 | 1.55 | 1.75 | 1.75 | 2.15 | 2.55 | 2.9 | 3.7 | 4.7 | 5.2 | 6.14 | 7.64 | 9.64 | 10.3 | 12.3 | 14.3 | 14.9 | 16.9 | 17.7 | 20.7 | 22.7 | 24.7 | 27.4 | 29.4 | 32.4 | 34.4 | 36.4 | 40.4 | 43.4 | 46.4 | 49.1 | 52.1 | 56.1 | 59.1 | 62.1 | 66.1 | 70.1 | 78.1 | 85.8 | 97.8 | 109.8 | 125.5 |

| 0.44 | 0.6 | 0.76 | 0.84 | 0.92 | 1.08 | 1.24 | 1.4 | 1.4 | 1.72 | 2.04 | 2.32 | 2.96 | 3.76 | 4.16 | 4.91 | 6.11 | 7.71 | 8.24 | 9.84 | 11.4 | 11.9 | 13.5 | 14.2 | 16.6 | 18.2 | 19.8 | 21.9 | 23.5 | 25.9 | 27.5 | 29.1 | 32.3 | 34.7 | 37.1 | 39.3 | 41.7 | 44.9 | 47.3 | 49.7 | 52.9 | 56.1 | 62.5 | 68.6 | 78.2 | 87.8 | 100 |

| 2.5 | 3 | 3 | 3.2 | 3.5 | 4 | 4.5 | 5 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 17 | 19 | 22 | 24 | 27 | 30 | 32 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 85 | 90 | 95 | 100 | 105 | 110 | 115 | 120 | 130 | 145 | 155 | 180 | 200 | 230 |

| 2.4 | 2.9 | 2.9 | 3.02 | 3.38 | 3.82 | 4.32 | 4.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.7 | 12.7 | 16.7 | 18.7 | 21.7 | 23.7 | 26.2 | 29.2 | 31 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 | 97.8 | 103 | 108 | 113 | 118 | 127.5 | 142.5 | 152.5 | 177.5 | 195.4 | 225.4 |

| 2.71 | 3.28 | 3.28 | 3.41 | 3.82 | 4.32 | 4.88 | 5.45 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.1 | 12.1 | 14.4 | 18.9 | 21.1 | 24.5 | 26.8 | 29.6 | 33 | 35 | 39.6 | 45.2 | 50.9 | 55.4 | 60.8 | 66.4 | 71.3 | 77 | 82.6 | 88.3 | 93.6 | 99.2 | 105 | 111 | 116 | 122 | 127 | 133 | 144.08 | 161.02 | 172.32 | 200.57 | 220.8 | 254.7 |

| - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - | 170 | 196 | 216 | 248 |

| 0.03 | 0.05 | 0.06 | 0.08 | 0.1 | 0.14 | 0.2 | 0.28 | 0.72 | 0.38 | 0.51 | 0.81 | 1.23 | 2.5 | 3.12 | 5.2 | 11.6 | 17.3 | 25 | 33.3 | 49.4 | 64.4 | 79 | 110 | 165 | 223 | 288 | 393 | 502 | 652 | 800 | 977 | 1220 | 1420 | 1690 | 1980 | 2300 | 2670 | 3040 | 3440 | 3930 | 4930 | 6820 | 8200 | 13000 | 17500 | 26500 |

| 材料 | 鋼 | 不銹鋼 | 有色金屬 | |

| 通用要求 | DIN 267 part 1 | |||

| 螺紋 | 公差 | 6H | ||

| 標準 | DIN 13 part 12,DIN 13 part 15 | |||

| 機械性能 | 等級 | ≤ M2.5:6 M3 ~ M39: 6,8,10 >M39:按協議 |

≤ M39:A2-70,A4-70 >M39:按協議 |

按協議 |

| 標準 | DIN 267 part 4 | DIN 267 part 11 | DIN 267 part 18 | |

| 公差 | 產品等級 | ≤ M16:A? >M16:B?? |

||

| 標準 | ISO 4759 part 1 | |||

| 表面處理 | - | 不經處理 | blank | blank |

| - | 電鍍 DIN 267 part 9①? 熱浸鍍鋅 DIN 267 part 10? DIN 267 part 21 applies to the expansion test? |

|||

| 表面粗糙度 | DIN 267 part 2 | |||

| 表面缺陷 | DIN 267 part 20 | |||

| 驗收及包裝 | DIN 267 part 5 | |||

| 備注 | ① Where a protective coating is applied e.g. an electroplated coating comflying with DIN 267 part 9, depending on the coating thickness required, it may be necessary, particularly in the case of tolerance class 6H nuts, to select a larger fundamental deviation than that assigned to the H position (see DIN 267 part 9 ). This, however, might impair the resistance of the bolt / nut assembly to stripping. | |||

蘇公網安備32058102001839

蘇公網安備32058102001839